The best concrete pumping services offer an array of services using a host of different types of pumps. They also employ people who care about the work that they do and work to ensure customer satisfaction for each job. If you are looking for commercial or residential concrete pumping service in the Gold Coast, we offer just about any type you could want.

Concrete pumping is the solution to most concrete needs whether it is for a building, retaining wall, roadway, high rise or apartment complex. At our concrete pumping service, we work to develop unique solutions that can be implemented quickly and that provide long-lasting results.

Ask us to do any of your concrete pumpings and we can manage it using a variety of pumping systems. We want to save you time and money with the concrete work you need. Ask us for more details as we use the latest concrete pumping equipment, some of the machines are mobile and others can pump at high-rise level. We will work with you to find out which pump is ideal for your project no matter how big or small it is. You can always check out Concrete Pumping Gold Coast Website

Extensive Range of Concrete Pumps

We use a wide range of pumps and all of them are the latest, most state-of-the-art pumps available. Our employees are specially trained to handle each piece of equipment. The work will get done fast and for a price that will make you happy. Because we care about our workers, they care about the work that they do. The end result is work that you are thoroughly pleased with, both structurally and aesthetically. Click here for more information.

Each of our employees and engineers has extensive knowledge of concrete pumping. We can take any job, no matter how difficult, and create a unique approach to pumping concrete for it. We use high-pressure pumps which can handle harsh mixes and get them delivered to any residential, commercial or high-rise building. We can also work to pump bridgework and tunnels.

Diverse Pumps

Because we work with an array of different, high-tech pumps we can manage any type of project. We use mobile or fixed tower placing booms. This means we can tackle complicated high-rise projects as well as sloped or difficult angles in residential projects. https://www.concretepumpingco.com.au/gold-coast/

We can use our diverse machines to pump concrete in a construction site or in a residential lot. The machines we use can be used under houses, on upper levels, at corners, or up and down stairs. You will not get that with wheelbarrow work. Get more detail on https://www.engr.psu.edu/concrete/Admixture/AdmixturesMain.htm

We are proud of the difficulty with which we can operate. We take great pride in creating unique solutions for the most difficult jobs and we enjoy seeing our customers happy. We will inspect any job site ahead of the pours and will make sure that the crew arrives on time.

We are committed to providing a safe workplace not just for our workers but also for our customers. We hold ourselves to a high level of safety and are certified in safety management.

Concrete pumps are used to transfer liquid concrete from its source to a casting spot on a construction site. The most common types of concrete pumps are line and boom pumps. Both pumps operate by the principle of two pistons – one which draws the concrete from the source and the other one that pushes the concrete into the discharge outlet pipe. The opening of the pistons is controlled by a valve.

Boom Concrete Pumps

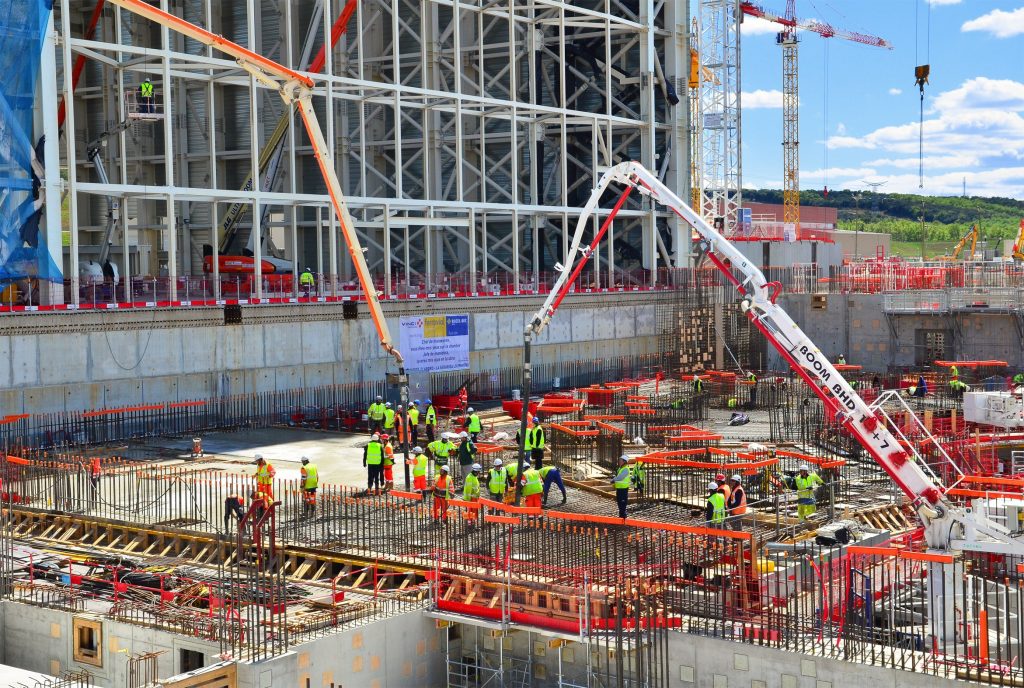

These are concrete pumps that are placed at one position for the whole process of concrete pouring at a construction site. Therefore, these are more of stationary concrete pumps. They have a bigger dimension than other pumps for placing on the ground. They also have a boom arm or crane attached in different lengths.

Concrete pumping to various heights such as in the construction of high-rise structures can be done using boom concrete pumps. This is because these pumps allow the pipeline to reach upwards, along, and below. This also allows for concrete to be cast into tight spots. Obstacles on the construction site can also be easily overcome using boom concrete pumps.

Line Concrete Pumps

These are compact pumps that are mostly used for small construction projects. Line pumps are attached to the back of the trailer or truck holding the liquid concrete. This arrangement is therefore known as truck mounted pump or trailer mounted pump.

Differences Between Line And Boom Pumps

- Attachment And Portability

One of the major differences between these two pumps is their method of attachment and portability. As earlier mentioned, boom concrete pumps are attached directly to the back of the trailer or truck. On the other hand, a line concrete pump is mounted onto a concrete truck. Boom pumps are complete units and a boom or robotic arm is attached to them to reach the required casting spot. Line pumps are more portable but they require hoses to be attached to the outlet of the machine. Click here for more detail. - Reach

Boom concrete pumps have the allowance to attach a boom so that they can reach greater heights. They are therefore suitable in the construction of high-rise structures. The booms attached come in up to four sections, with each reaching 16 feet upwards. This means that booms with five sections can reach up to 80 feet in the air. Line concrete pumps are mostly used for horizontal pumping and have hoses that can reach up to 1500 feet. - Volume

Boom pumps are generally used for large concrete jobs, with their output exceeding 150 cubic yards/hour. Line pumps have a smaller output, which can range between 20 and 90 cubic yards/hour. This means that they are generally used for small construction works. - Cost

From their applications, one can tell that line pumps are cheaper than boom pumps. Line pumps can cost up to a third of what a boom pump costs.

For concrete pumping history, visit: https://www.academia.edu/6229496/Concrete_Pumping_History

Both line and boom concrete pumps are used in the pumping of liquid concrete from a truck or trailer to a casting spot on a construction site. These pumps use the same operation principle but differ in their volumes, reach, cost, portability, and attachment.

Make sure the pump and hose are cleaned out from the previous pours. A clean hose is essential for a good pour. Note that cleaning it may be your first step if the concrete pump has not been properly taken care of before you set it up to pour.

The next step assumes that you have set the pump up near the site where the concrete is needed. It also assumes that you have a clean hose or that you have just completed the cleaning process.

Set the hose up with the proper straps and cables and secure it to a fixed point on the boom. The next step is to prime it. You want to lubricate it using a gel so that the horizontal section has the mix running down the lower half and allows the upper part semi-dry. The concrete mix can still get through the upper portion if this is the case. Visit: http://peakconcretepumping.com/types-of-services-from-concrete-pumping-goldcoast/ for types of services from concrete pumping.

Turn on the pump and have someone working on priming the hose. This step involves pushing it up. Trust gravity to bring it down as it needs to. Primer will get to the high point of the boom and then flood down to wet the rest of the pipe. Count the strokes so you can be consistent once the concrete mix starts flowing downwards. You want the mix to come out smooth and counting is a good way to get it to do so.

As the pour comes out it will be wettest first. Hold off on pumping to avoid making mud out of the mist that is up at the top. Give the pump time to get the mix flowing properly continue pumping the same as before but watch out for any pressure buildups.

The more the pumping goes on the more you will get a feel for it. You will sense the pump when it becomes harder to pump. This is a sign it might be plugging up. Adjust your pumping to accommodate this. Run it on half-throttle as this helps you feel the pressure building sooner. This lets you change your pumping strokes as needed to prevent a clog. Click here for more information regarding impingement kinematics between circular and pumping strokes.

Even if a plug builds you can fix it. Work it out using the slump to let the mud mix correct itself and keep priming until the mix is all the way out.

Do not prime dry concrete. This will almost certainly cause it to plug up. Plugging up the chute of the machine is a bad thing. This is sure to stop the water and concrete mix from blending correctly. Think in terms of keeping everything flowing together in the right balance. Keep the pump moving.

Remember that properly priming the pump is the key to a successful, smooth pour. Once you have the priming done and you watch for any plugs as the pour goes on you should have success in pouring the concrete just right. Also, make sure to have a clean hose before you even start pumping and pouring concrete.